Be Careful When Working With Fiber Optic Cable

srijeda , 20.07.2016.It’s known that safety issues or hazards are commonplace in both copper and fiber cabling installation, faced by installers. And when it comes to this topic, many people think that copper cabling installation need more attention and caution, since they carry electricity. In comparison, optical fibers are safer because of the light they carry. But actually, this concept is misplaced. As to fiber optic cables, whose ends are capped with the same or different connectors (e.g. ST ST fiber cable and LC to SC cable), they carry data in the form of light which can bring harms to the eyes.

Many people are unaware of the problems that fiber poses. Some installers don’t think much of fiber optic issues, and they don’t take proper safety precautions to avoid the many hazards that can be caused by fiber optics. Working with fiber optic cables needs much caution, and installers need to do the two points for safety: fiber fragment disposal and eye protection.

Fiber Fragment Disposal

When an installer is trimming, stripping, or cutting fibers, tiny fragments may fall where it will--on the top of the table where the job is being done, at the bottom of the raised floor, or maybe into a cup of coffee that is close by. The scraps may even be brushed into a nearby garbage can. Then what happens if someone rests his or her hand on top of that fiber scrap? The glass is transparent and the scrap is probably small, so unless the person is the one who did the terminating, he or she may not know the hazard is there. Because of this, workers should not eat or drink in a fiber optic work area since a fiber scrap could fall onto their food or in their drink.

It’s important to keep in mind that tiny fiber fragments can penetrate the skin and become embedded, causing a serious irritation. Ingested fibers can cause internal damage since they are light enough to float in air.

To avoid such potential danger, these safety kits can be used:safety glasses (for keeping eyes free of scraps), a black polishing/work mat (the black surface makes it easier to locate fiber scraps), Teflon-coated tweezers to remove splinters (regular tweezer ends break fiber scraps), and a bifurcated swipe (for cleaning fiber ends and sterilizing the tweezers for splinter removal). One of the most popular components of the kit is the fiber-scrap trash can, which provides a single place for disposing of bits of fiber. Once full, the small trash can may be incinerated.

Eye Protection

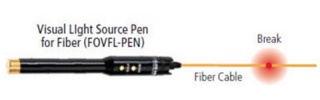

After finishing cable installation, many installers unfamiliar with fiber-optic technology may look at the fiber’s end to verify that light is being transmitted, which causes the loss of visual acuity or blind spots because the beam is focused on the retina. What’s even worse is that the light used in fiber- optic communications systems is in the infrared range and is not visible to the human eye.

So when working with fiber optics, all workers performing any splicing or termination activities should always wear safety glasses with side shields. Any other people or site managers entering the work area should wear safety glasses with side shields also. Unless an installer is absolutely sure there is not a light source at the other end, they should never look directly into the end of the cable. A power meter can be used to make certain the fiber is dark.

Other Safety Considerations

Chemicals: Fiber optic splicing and termination use various chemical cleaners and adhesives as part of the processes. Normal handling procedures for these substances should be observed. Even simple isopropyl alcohol, used as a cleaner, is flammable and should be handled carefully. Manufacturers will supply "material safety data sheets" (MSDS) on request or they may be found on the Internet.

Splicing hazards: Fusion splicers use an electric arc to make splices, so care must be taken to insure no flammable gasses are present in the space where fusion splicing is done.

No Smoking: Smoking should also not be allowed around fiber optic work. The ashes from smoking contribute to the dirt problems with fibers, in addition to the possible presence of combustible substances (and, of course, the health risks.)

Safety Tips

While working with fiber optics, the worker needs a well-ventilated and well-lit work area. Workers must avoid smoking while working with fiber optics.

Also, all food and beverages should be kept out of the work area. Workers can wear disposable aprons to keep fiber particles off their clothing. Before leaving the work area, an employee should always check their clothing for pieces of stray fiber, and if any are found, they can remove it with double-sided tape.

A worker should wash their hands thoroughly before touching their eyes, and contact lens wearers should wash their hands before touching their lenses. Workers should also read all instructional material before handling chemicals.

A disposable container that can be tightly closed must be used for fiber scraps. When finished with a fiber optic job, all cut fiber pieces should be disposed of properly along with any used chemicals and containers. The work area should be thoroughly cleaned when job is completed.

Conclusion

Understanding the potential dangers and knowing the simple fiber optic safety tips can keep the working environment clean and safe for workers, so as to avoid hazards. As an outstanding fiber patch cord manufacturer, Fiberstore supplies various kinds of fiber optic cables for your cabling installation, test- and quality-assured. You can have a try here.

Oznake: fiber optic cables, ST ST fiber cable, fiber cabling installation, fiber fragments, eye protection, fiber patch cord manufacturer

komentiraj (0) * ispiši * #

Pros & Cons of Fiber Optic Networks

petak , 01.07.2016.As one of the latest and most popular technologies utilized for information transmission from one point to another, the fiber optic communication has gained more and more importance in data centers nowadays. Since its introduction, fiber optic communication has revolutionized the telecommunications industry, transforming into the fiber optic broadband Internet service enjoyed by people today. With the obvious advantages, fiber optic cables have become an essential component in fiber optic communications. Terminated with connectors on ends, these cables (e.g. SC SC fiber cable) carry the light signals generated by the transmitter to the receiver. Although this fiber optic connection has been widely used in data centers because of its high data transmission speeds over long distance, fiber optics, like many other things, also has two sides: the pros and cons. Here this article delves into the advantages and disadvantages of fiber optic networks.

Pros of Fiber Optics

Great Immunity & High-quality Connections: Since the fiber core is made of glass, which is an insulator, no electric current can flow through. It’s immune to electrometric interference and radio-frequency interference (EMI/RFI), crosstalk, impedance problems, and more. More specifically, fiber optics are highly resistant to EMI and have a low rate of bit error. EMI is a disturbance caused by electromagnetic radiation from an external source. This disturbance can interrupt or degrade the performance of a conventional metallic cable connection and can be caused by an object that carries electrical currents, such as power lines or even the sun. Fiber optics are also resistant to corrosion, making them a good option for beachfront properties where copper cabling would otherwise be susceptible to degradation by salt and seawater.

Great Security: Security is a major concern for some companies, enterprises or organizations, whether small or big. With fiber optic cables, the data carried on are very safe. Fiber optics don’t radiate signals and it’s really difficult to tap or listen in the passed through information. Besides, once there occurs any physical break, it’s extremely to identify since this break will have impacts on the whole system. Fiber optic networks also enable you to put all your electronics and hardware in one central location, instead of having wiring closets with equipment throughout the building.

Scalability & Design: Fiber optics are much more scalable in nature as new equipment can be added easily and laid over the original fiber. Wavelengths can be turned on or off on demand, which allows for the easy provisioning of services and quick scaling for a growing business. Fiber optic cables are also much smaller in size and lighter weight than copper wiring. These fibers can typically be put in place in preparation for growth needs up to 15 to 20 years in the future. Although growth is often speculative, spare fibers can be included for future requirements to accommodate growth. Alternatively, additional cables can be put in place at a later time to make way for network expansion.

Cons of Fiber Optics

It’s well known that fiber optic cable provides more bandwidth than copper, and can carry more information with greater fidelity than copper wire. And no one can defy its advantages. But it’s also clear that fiber optic networks have several weak points.

Physical Damage: As mentioned above, fiber optic cable is thinner and lighter than copper wiring, so it makes for a more delicate system. Just because of its small size, fiber optic cable can be easily cut by accident during building renovations or rewiring. In addition, as fiber optic cables can transmit much more data than metallic networks, you would need fewer cables to service a larger number of people. This means that cutting just one cable could disrupt service for a large number of businesses and individuals. Additionally, wildlife also poses a threat, as the fiber cable jackets are intriguing to some species. Tunneling animals and rodents may chew through the cable, while many insects can find the cabling palatable. Anything that can wrap itself around the cable can also cut off the transmission. Fibers are also sensitive to bending, making laying fibers around corners a tricky business. Fiber optic networks are also susceptible to radiation damage or chemical exposure.

Fiber Fuse: At high power, fiber optic networks are susceptible to something known in the industry as “fiber fuse”. This occurs when too much light meets with an imperfection in the fiber, which can destroy long lengths of cable in a short amount of time.

Short-Term Large Budget: Judging from the long-term running, it’s cost-effective. But when considering for short-term use, it’s costly to implement fiber optic systems. Special test equipment is often required along with installers that have skilled knowledge about laying a fiber optic network. Fiber endpoints and connection nexuses also require special equipment and setup. In addition, it may take specialized equipment to diagnose an issue with a fiber optics network, making for higher-cost fixes if the cables sustain damage.

Conclusion

Although there some several weaknesses, fiber optics technology has still dominated the telecommunication market. And fiber optic network is selected as the main communication way. To ensure efficient fiber optic network, it’s important to choose the high-quality fiber optic products. Here Fiberstore is highly recommended for its reliable products, including optical transceivers (say SFP modules), fiber optic cables (SC SC fiber cable), as well as testing equipment used in cable installation, and so on. You can try it!

Oznake: fiber optics, fiber optic cables, SC SC fiber cable, optical transceivers, SFP+ modules

komentiraj (0) * ispiši * #

Fiber Optics: Do You Know Its History & Advantages?

srijeda , 22.06.2016.As we all know that the medium is considered as the simplest form of fiber optics, which is used to carry information from one point to another in the form of light. It's comprised of a transmitter used to generate the light signal, a fiber optic cable that functions as a conduit for pulses of light to travel over distances,, and a receiver to accept the light signal transmitted. In practical use, fiber systems are often deployed as the alternative solutions to traditional copper-based communications systems, since fiber optic cables outperform copper cables in less signal loss and immunity to electromagnetic interference (EMI). Of course, the advantages of fiber optics are denifinely not confined to these two points. Read this article and the following detail the several strong points of fiber optics used in communication systems, as well as its history.

Fiber Optics: History

In 1880, the photophone was invented, a great inventory used to speak into a microphone which would then cause a mirror to vibrate. The sun's light would strike the mirror, and the vibration of the mirror would transmit light across an open distance of about 656ft (200m). The receiver's mirror would receive the light and cause a selenium crystal to vibrate, causing the noise to come out on the other end. Although the photophone was successful in allowing conversation over an open space, it had a few drawbacks: it did not work at night, in the rain or if someone walked between the signal and receiver. Then this idea was given up.

In 1950s, the laser was invented. This device was a finely controlled beam of light that could transmit information over long distances. Unfortunately, the same drawbacks also plagued the laser. Although it could be used at night, it did not work during rain, fog or at any time when a building was erected between the sender and the receiver.

Scientists at Corning developed the first practical fiber optic cables in the 1970s, based on the idea of "total internal reflection". This is the principle that fiber cables are built upon, and it basically means that an optical fiber consists of a core of transparent glass, surrounded by outer layer, (called "cladding") of slightly less transparent glass which reflects the light back into the core.

What Makes Fiber Optics Special?

What is special about fiber optics? As mentioned above, fiber optic cables are made out of glass, and carry pulses of light energy. The idea of a flexible piece of glass sounds a bit counter-intuitive, but in some ways, fiber optic cables are stronger and more durable than copper cables.

Nowadays, fiber optic cables are used for many different telecommunication applications, like data centers, data warehouses, server farms, SANs, and LANs. But actually, in their practical use, there exists a common question. One may find himself faced single-mode fibers (SMFs) and multi-mode fibers (MMFs) which are terminated with different connectors, such as LC (LC fiber cable), SC (LC to SC cable), MTP/MPO (MTP cable). When such things occur, it’s important to keep in mind that SMFs and MMFs are not compatible with each other, and can't mix them together between two end points.

Fiber Optics: Advantages

Why is fiber optics used in telecommunications? There are several reasons that make fiber systems more popular than copper ones.

Large Bandwidth & Long Distance

Bandwidth refers to the amount of data that can be passed along a cable in a given time period. If we think of cables as pipes, then bandwidth is the amount of water that can flow through the pipe in a second. The bigger the pipe, the more water can flow. Consider a normal communication cable that may be used to carry a single phone call. It is built out of copper, and may have the bandwidth of a normal drinking straw. By comparison, a fiber cable of the same physical size would provide more bandwidth.

Since fiber optic signal is made of light, very little signal loss occurs during transmission, and data can move at higher speeds and greater distances. In most cases, copper cables are limited to a range of 100meters or less. In contrast, the relatively small diameter and light weight of fiber optic cables can allow a wide range of distance reaches from 550meters to dozens of kilometers, which makes fiber ideal for applications where signals have to travel over long distances.

Immunity & Reliability

Fiber optics provides extremely reliable data transmission. It’s completely immune to many environmental factors that affect copper cable. The core is made of glass, which is an insulator, so no electric current can flow through. It’s immune to electrometric interference and radio-frequency interference (EMI/RFI), crosstalk, impedance problems, and more. You can run fiber optic cable next to industrial equipment without worry. Fiber is also less susceptible to temperature fluctuations than copper and can be submerged in water.

Security

The data is safe with fiber cable which doesn’t radiate signals, letting information difficult to be tapped. More specifically, the dielectric nature of fiber optic cable makes it impossible to remotely detect the signal being transmitted within the cable. If the cable is tapped, it’s very easy to monitor because the cable leaks light, causing the entire system to fail. If an attempt is made to break the physical security of your fiber system, you’ll know it. Fiber networks also enable you to put all your electronics and hardware in one central location, instead of having wiring closets with equipment throughout the building. They are very attractive for use in governmental institutions, finance/banking and other environments with major security concerns.

Summary

It's obvious that fiber optics has a growing usage in both private and public networks. It's able to transmit signals over significantly distance at high speed and large amount, extremely suitable for voice and data links. As an outstanding fiber patch cord manufacturer, Fiberstore provides various kinds of fiber optic cables terminated with the same or hybrid connectors on the ends to cover countless applications, including the above mentioend LC fiber cable, LC to SC cable, MTP cables, and so on. They are all supplied at cost-effective prices. Really worth your try.

Oznake: fiber optic cables, LC to SC cable, LC fiber cable, SMFs, MMFs, fiber patch cord manufacturer

komentiraj (0) * ispiši * #

Comparison Among Twisted Pair, Co-axial Cable and Fiber Optics

srijeda , 15.06.2016.In communication systems, massive bundles of wires and cables are used to transport data between servers and other equipment. These cables can be twisted pair cables, co-axial cables and fiber optic cables. Since all these three types can be applied to network communications, it’s essential to determine which cable type is the best for the reliable and efficient data transfer, meaning that a basic understanding of their respective designs and features is necessary. This text aims to compare these three kinds and discuss the differences among them.

Twisted Pair Cable

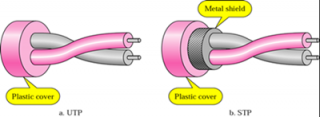

Twisted pair cable is a kind of wiring in which two conductors of a single circuit are twisted together, with one conductor serving as the forward circuit and the other as the return circuit. The twisted cabling design helps to reduce noise from outside sources and crosstalk on multi-pair cables, making it suitable for use in the field of telecommunication for a long time.

Twisted pair cable comes in two versions (image shown below): unshielded twisted-pair (UTP) and shielded twisted-pair (STP). Since UTP cable lacks shielding, it’s more susceptible to interference from electronic devices. Or in another way, STP cable consists of a foil jacket which helps to prevent crosstalk and noise from outside source. STP is commonly used in Token Ring networks and UTP is in Ethernet networks.

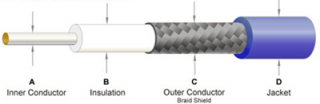

Co-axial Cable

Co-axial cable, or sometimes referred to as coax, is a type of cable that has four layers. That is, at the core is an inner conductor which is surrounded by a foam insulation, symmetrically surrounded by a woven braided metal shield, then covered in a plastic jacket (just as the following picture shows). Because of its insulating property, coaxial cable can carry analogy signals with a wide range of frequencies. It’s seldom used in computer networks anymore, but widely used in cable television services and video connections, like those used by closed circuit surveillance systems.

There are two coaxial cables: 75 Ohm and 50 Ohm. The former is primarily used to transmit a video signal, like television signals over cable. While the main application of the latter is transmission of a data signal in a two-way communication system. Other typical applications include computer Ethernet backbones, wireless antenna feed cables, GPS (Global Positioning Satellite) antenna feed cables and cell phone systems.

Fiber Optic Cable

Fiber optic cable is the complete assembly of fibers, and uses light pulses to transmit information down fiber lines instead of using electronic pulses to transmit information down copper lines. Each of the optical fiber elements is individually coated by plastic layers and contained in a protective tube. A fiber optic cable can accommodate many wavelengths (or channels), able to accommodate ever-increasing data capacity requirements. When terminated with LC/SC/ST/FC/MTRJ/MU/SMA connectors on both ends, such as LC-LC, LC-ST, SC-SC, ST-ST, LC SC cable, fiber optic cables can achieve fiber link connection between equipment during fiber cabling.

Comparison Among Three Cables

Before delving into comparison between these three cables, a table about their respective strengths and weaknesses is available.

Comparing Twisted Pair & Co-axial Cable

Both twisted pair and co-axial cable can support network speeds in both the megabit and gigabit ranges. Both are susceptible in varying degrees to signal interference, as well as signal leakage. (Signal interference occurs when external signals interfere with transmission inside the cable, and signal leakage means that signals inside the cable leak out and become a source of interference to other devices.) Coaxial cable, being of a standard design, varies little in its susceptibility to interference. For twisted pair cable, however, the cable’s resistance to interference depends in large part on the degree to which the twisting scheme remains in place, and therefore can vary widely.

Comparing Twisted Pair & Fiber Optic Cable

Judging from cable and installation costs to tooling and transceivers, twisted pair, here mainly refers to UTP, is much less costly than fiber optic cable. The one obvious difference lies in the quality. Passive to active UTP systems offer performance similar to fiber, providing noise immunity, attenuation compensation, surge protection and ground loop isolation. Because of this point, those users, who once deployed fiber optic cables for runs beyond the range of co-axial cable, now choose UTP for transmission. Fiber optic cable is good for extremely long runs (over one mile) or for safety when video is run in the same conduit with high voltage.

Allowing for distance, if cable runs less than 250 feet, co-axial cable is probably the best option. Between 250 and 8,000 feet, UTP wire is often the best one. If the runs are more than 8,000 feet, it’s advised to select fiber optic cable.

Conclusion

While deciding whether to use co-axial cable, twisted-pair, or fiber optic cable for transmission, it’s imperative to collect the basic information about them, and take the cost, cable runs and other external conditions into consideration. In Fiberstore, you can find different types of UTP cable (eg. Cat 5, Cat5e, Cat6) and various fiber optic cables (say LC SC cable mentioned above, SC to SC fiber patch cable). You can go to Fiberstore to know more information about both copper and fiber optic cables.

Oznake: twisted pair, co-axial cables, UTP, STP, fiber optic cables, LC SC cable, SC to SC fiber patch cable

komentiraj (0) * ispiši * #

Fiber Optic Cable Basics: Construction & Certification Measurements

srijeda , 11.05.2016.Being one of the most popular and cost-effective means for communications, fiber optic cables have been installed in the backbone for years, as fiber makes communications at the speed of light possible. And their greater bandwidth and lower attenuation allow for longer distances and more channels compared with copper wires. The number of articles and papers on fiber optic cables is so large. Some are about their classifications (tight buffer/distribution/breakout/loose tube), some are on their advantage discussion (speed, distance, security), and others are meant to touch upon their related connector color codes (orange, yellow, blue). While in this article, still some basic information is included, like the construction and certification measurements.

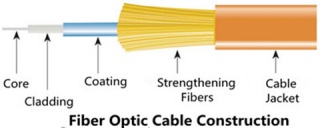

Fiber Optic Cable Construction

Fiber optic cable construction includes a core, cladding, coating, strengthening fibers, and a cable jacket.

Fiber Core

Fiber core refers to the light-carrying element at the center of the cable, transmitting optical data signals from an attached light source to a receiving device. The core is a single continuous strand of extruded silica glass or plastic that’s measured in microns (µm) by the size of its outer diameter. The larger the core, the more light the cable can carry. The two most common multi-mode sizes are 50 and 62.5 microns. Single-mode cores are 8.5–9 microns.

The cores of OM1 and OM2 multi-mode fiber (MMF) are made differently than the cores of laser-optimized OM3 and OM4 cable. OM1 and OM2 have a small defect in the core called an index depression. This enables them to be used with LED light sources. In contrast, OM3 and OM4 are manufactured without the center defect, which enables them to be used directly with VCSELS for greater speeds and distance. These OM3 and OM4 MMFs are widely used in Gigabit applications, especially in 10GbE transmission when they are used as the medium for 10GbE transceiver modules (ie. SFP-10G-SR).

Cladding

The optic cladding surrounds the fiber core. It functions as a boundary that contains the light waves and causes the internal refraction, enabling light to travel through the length of the fiber segment.

Coating

There is a protective acrylate coating that surrounds the core and cladding to protect them. This coating keeps the glass from dust and scratches that can affect fiber strength.

Strengthening Fibers

These components are to protect the core against crushing forces and excessive tension during cable handling, especially the installation and termination process. The materials can range from aramid yarn to wire strands to gel-filled sleeves.

Cable jacket

Fiber optic cable jacket is available in PVC and plenum-rated versions. The former type is typically used for patch connections in the data center, wiring closet, and at the desktop, while the latter kind is deployed when you need to route a cable through the buildings air plenum. Plenum cable has a flame-resistant jacket to inhibit the spread of fire.

Performance Measurements

Unlike copper cable, it’s easier to certify fiber optic cable, since it’s immune to electrical interference. When certify it, the following measurements are necessary.

Attenuation/Decibel Loss

Attenuation means the decrease of signal strength as it travels through the fiber optic cable, measured in decibels/kilometer (dB/km). Generally speaking, attenuation problems are more common to MMF.

Return Loss

This loss refers to the amount of light that is reflected from the far end of the cable back to the source. The lower the number, the better. For example, a reading of -60 decibels is better than -20 decibels. Like attenuation, return loss is usually greater with MMF.

Graded Refractive Index

This concept measures how the light is sent down the fiber, commonly mensurated at wavelengths of 850 and 1300nanometers. Compared to other operating frequencies, these two ranges yield the lowest intrinsic power loss (This is valid for MMF only.)

Propagation Delay

This is the time a signal takes to travel from one point to another over a transmission channel.

Optical Time-domain Reflectometry (OTDR)

This enables you to isolate cable faults by transmitting high-frequency pulses onto a cable and examining their reflections along the cable. With OTDR, you can also determine the length of a fiber optic cable because the OTDR value includes the distance the optic signal travels.

Notes on Fiber’s Speed & Modal Bandwidth

After introducing basic information about fiber optic cable, here, I’d like to mention two commonly-seen concepts: the first one, fiber’s speed which is not meaning the speed of the signal in the fiber, but the bandwidth potential of the fiber.

The second one, modal bandwidth which is caused by the fact that light in MMF travels in rays or "modes" that take different times to get to through the fiber, thus dispersion occurs. The longer the fiber, the greater the effect. This is the incentive driving fiber manufacturers to develop better MMFs.

Conclusion

Fiber optic cables are suitable for backbone, horizontal, and desktop applications, providing extremely reliable data transmission. They are less susceptible to temperature fluctuations, and can even be submerged in water or under sea. Fiberstore fiber optic cables come in various types with detailed specifications displayed for your convenient choice. These quality cables are designed with best-in-class performance. Besides, you can also find Push-Pull MPO cable, a kind of fiber patch cable with push-pull MPO connector here. For more information about fiber optic cables or patch cords, you can visit Fiberstore.

Oznake: fiber optic cables, MMF, 10GbE transmission, SFP-10G-SR, patch cords, Push-Pull MPO cable

komentiraj (0) * ispiši * #