Pros & Cons of Fiber Optic Networks

petak , 01.07.2016.As one of the latest and most popular technologies utilized for information transmission from one point to another, the fiber optic communication has gained more and more importance in data centers nowadays. Since its introduction, fiber optic communication has revolutionized the telecommunications industry, transforming into the fiber optic broadband Internet service enjoyed by people today. With the obvious advantages, fiber optic cables have become an essential component in fiber optic communications. Terminated with connectors on ends, these cables (e.g. SC SC fiber cable) carry the light signals generated by the transmitter to the receiver. Although this fiber optic connection has been widely used in data centers because of its high data transmission speeds over long distance, fiber optics, like many other things, also has two sides: the pros and cons. Here this article delves into the advantages and disadvantages of fiber optic networks.

Pros of Fiber Optics

Great Immunity & High-quality Connections: Since the fiber core is made of glass, which is an insulator, no electric current can flow through. It’s immune to electrometric interference and radio-frequency interference (EMI/RFI), crosstalk, impedance problems, and more. More specifically, fiber optics are highly resistant to EMI and have a low rate of bit error. EMI is a disturbance caused by electromagnetic radiation from an external source. This disturbance can interrupt or degrade the performance of a conventional metallic cable connection and can be caused by an object that carries electrical currents, such as power lines or even the sun. Fiber optics are also resistant to corrosion, making them a good option for beachfront properties where copper cabling would otherwise be susceptible to degradation by salt and seawater.

Great Security: Security is a major concern for some companies, enterprises or organizations, whether small or big. With fiber optic cables, the data carried on are very safe. Fiber optics don’t radiate signals and it’s really difficult to tap or listen in the passed through information. Besides, once there occurs any physical break, it’s extremely to identify since this break will have impacts on the whole system. Fiber optic networks also enable you to put all your electronics and hardware in one central location, instead of having wiring closets with equipment throughout the building.

Scalability & Design: Fiber optics are much more scalable in nature as new equipment can be added easily and laid over the original fiber. Wavelengths can be turned on or off on demand, which allows for the easy provisioning of services and quick scaling for a growing business. Fiber optic cables are also much smaller in size and lighter weight than copper wiring. These fibers can typically be put in place in preparation for growth needs up to 15 to 20 years in the future. Although growth is often speculative, spare fibers can be included for future requirements to accommodate growth. Alternatively, additional cables can be put in place at a later time to make way for network expansion.

Cons of Fiber Optics

It’s well known that fiber optic cable provides more bandwidth than copper, and can carry more information with greater fidelity than copper wire. And no one can defy its advantages. But it’s also clear that fiber optic networks have several weak points.

Physical Damage: As mentioned above, fiber optic cable is thinner and lighter than copper wiring, so it makes for a more delicate system. Just because of its small size, fiber optic cable can be easily cut by accident during building renovations or rewiring. In addition, as fiber optic cables can transmit much more data than metallic networks, you would need fewer cables to service a larger number of people. This means that cutting just one cable could disrupt service for a large number of businesses and individuals. Additionally, wildlife also poses a threat, as the fiber cable jackets are intriguing to some species. Tunneling animals and rodents may chew through the cable, while many insects can find the cabling palatable. Anything that can wrap itself around the cable can also cut off the transmission. Fibers are also sensitive to bending, making laying fibers around corners a tricky business. Fiber optic networks are also susceptible to radiation damage or chemical exposure.

Fiber Fuse: At high power, fiber optic networks are susceptible to something known in the industry as “fiber fuse”. This occurs when too much light meets with an imperfection in the fiber, which can destroy long lengths of cable in a short amount of time.

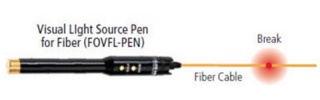

Short-Term Large Budget: Judging from the long-term running, it’s cost-effective. But when considering for short-term use, it’s costly to implement fiber optic systems. Special test equipment is often required along with installers that have skilled knowledge about laying a fiber optic network. Fiber endpoints and connection nexuses also require special equipment and setup. In addition, it may take specialized equipment to diagnose an issue with a fiber optics network, making for higher-cost fixes if the cables sustain damage.

Conclusion

Although there some several weaknesses, fiber optics technology has still dominated the telecommunication market. And fiber optic network is selected as the main communication way. To ensure efficient fiber optic network, it’s important to choose the high-quality fiber optic products. Here Fiberstore is highly recommended for its reliable products, including optical transceivers (say SFP modules), fiber optic cables (SC SC fiber cable), as well as testing equipment used in cable installation, and so on. You can try it!

Oznake: fiber optics, fiber optic cables, SC SC fiber cable, optical transceivers, SFP+ modules

komentiraj (0) * ispiši * #

A Rundown of Fiber Optic Connectors

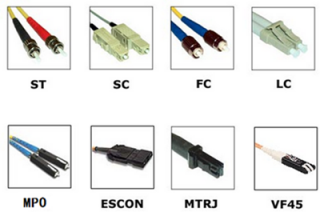

petak , 17.06.2016.During the rapid development of fiber optic technologies over the past decades, fiber product manufacturers and companies have released countless sophisticated equipment, during which the so-called “better mousetrap”—fiber optic connectors attract users’ attention. These smart connectors are used to terminate at the ends of fiber optic cables to form fiber optic jumper, like fiber cable LC to LC. Since a variety of splice options are available to fiber network planners today, connector types are diversified, eg. ST, SC, LC, MTP/MPO connectors. Each connector has its own unique design and therefore, pros and cons. Then question occurs, how to choose the suitable ones that are lower loss, lower cost, easier to terminate or to solve some other perceived problems? Have some ideas? If not, don’t worry. Here is a rundown of several leading connector types, introducing their strengths and weaknesses respectively.

Fiber Optic Connector Design

Most fiber optic connectors are known to be pluggable male connectors with a protruding ferrule that holds the fiber optic cables and aligns them for mating. They use a mating adapter to mate the two connector ferrules that fit the securing mechanism of the connectors (bayonet, screw-on or snap-in.). The ferrule design is also useful as it can be used to connect directly to active devices like LEDs, VCSELs and detectors. Image below helps you to get the idea of different connector sizes.

Fiber Optic Connector Color Codes

In earlier ages, single-mdoe connectors are always in yellow, while multi-mode ones in orange, black or gray. But the advent of such metallic connectors as FC and ST made color coding difficult, so colored boots were often used. The TIA 568 color code for connector bodies and/or boots is Beige for multi-mode fiber (MMF), and Blue for single-mode fiber (SMF), and Green for APC (angled) connectors.

Fiber Optic Connector Types

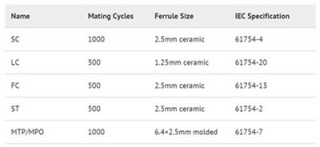

Table listed below shows differences among several most common fiber optic connectors.

SC Connector

SC, sometimes referred to as square connector, was developed by the laboratories at Nippon Telegraph and Telephone (NTT) in the mid-eighties. Standardized in TIA-568-A, the SC has a push-pull coupling end face with a spring loaded 2.5mm ceramic ferrule. At first, SC was not widely used because of its high cost, but with manufacturing costs coming down, it slowly grew in popularity in datacoms and telecoms applications including point to point and passive optical networking.

LC Connector

LC connector, licensed by Lucent Technologies, is a small form factor connector that utilizes a latch as opposed to the SC locking tab, and with a 1.25mm ferrule, half the size of the SC. It’s just because of its smaller size, LC becomes increasingly popular in datacoms and other high-density patch applications, as its combination of small size and latch feature make it ideal for densely populated racks/panels. With the introduction of LC compatible transceivers (say SFP-10G-SR) and other networking components, its steady growth in the communication arena is likely to continue.

FC Connector

Different to the plastic bodied SC and LC, FC uses a round screw-type fitment made from nickel-plated or stainless steel. The connector end face relies on an alignment key for correct insertion and is then tightened into the adaptor/jack using a threaded collet. Despite the additional complexity both in manufacturing and installation, it’s still the connector choice for precise measuring equipment such as OTDRs.

ST Connector

ST was developed by AT&T. Judging from appearance, ST and FC are almost the same, except that ST uses a bayonet fitment rather than a screw thread. The introduction of SC and LC has reduced the usage of ST and FC, since SC and LC deliver similar performance to ST and FC, but both have less expensive components and are quicker to connect. Additionally, ST cannot be terminated with an angled polish, which limits use in SMF and FTTH applications.

MTP/MPO connector

Just like SC, MT ferrule connector is also NTT’s invention coming in the 1980s. But this technology has only recently become popular under branded versions of the multiple fiber push-on/pull-off connector, such as MTP and MPO. It is larger than the other connectors but for good reason - it can support up to 24 fibers in a single ferrule. They are extensively used in high density patch environments such as data centers they are used extensively, both at single mode and multi-mode wavelengths.

It’s known that the sequence of the fibers cannot physically be changed after termination, so MTP/MPO connector is supplied with a fan-out assembly at the opposing end, such as LC. This allows the operator to change channels simply by re-patching the fanned-out side of the cable.

Conclusion

After description, it’s easy to identify these connectors and choose the right ones for your networking use according to their design and usage. Fiberstore supplies various kinds of connectors with high quality and at low prices. Besides, connector compatible fiber patch cords are also available, including fiber cable LC to LC mentioned above, SC SC fiber cable, ST ST fiber cable, and so on. You can visit Fiberstore to know more information about fiber optic connectors and their compatible fiber cables.

Oznake: fiber optic connectors, SC, LC, FC, st, MTP/MPO, fiber cable LC to LC, SC SC fiber cable

komentiraj (0) * ispiši * #