Seven Tips for the Cable Installation

četvrtak , 18.08.2016.Cable installation can be a finicky thing. People without appropriate knowledge and training can not be capable of running cables, otherwise they will end up with network failure. End users might have the experience of running telephone cables, so that they want to take the risk of wiring network cables. In fact, telephone cables can tolerate quite a lot of errors, but that is not the case of the data cabling as it is quite sensitive to cable errors. Therefore, to avoid potential network error and reduce your risks of costly mistakes, here are several things you should know before the cable installation.

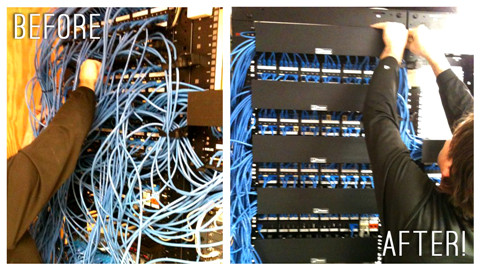

Using Cable Management

The first thing you should bear in your mind is that the cabling work won’t stop with the initial installation. More cables and optical devices will be added. Thus to make sure that you label appropriate cables, color-code cables, or implement some other kind of process to make it easier to identify cables later on. What’s more, adding ladder rack, rack-based cable management makes ongoing maintenance much, much easier. The following image can easily illustrate the importance of fiber cable management.

Running Cable in Parallel With Electrical Cables

Data cabling used UTP (unshielded twisted pairs) to achieve its goals. The magnetic field generated by the low voltage running through the cable is a critical component of the communications chain. When you run this unshielded cabling in parallel with electrical cables, that magnetic field is disrupted and the communication becomes noisy and garbled. In many cases, transmissions will simply not make it from Point A to Point B. In other cases, transmission rates will slow to a crawl as communications are constantly retried. If you have to go near electrical power lines, cross them in perpendicular instead. From a personal experience, a newly installed coaxial cable can be easily out of work if they are twisted around the overhead electrical cabling that ran between the two buildings.

Minding Distance Limitations of Your Cabling

It is known that the typical distance limitations for UTP cabling with up to 1 Gbps is 100 meters. However, if you're running cabling for some other purposes, such as 10 Gbps or 40 Gbps, be mindful of the distance limitations associated with the type of cabling you intend to use. For example, if you intend to run 10 Gbps for up to 100 meters over twisted pair cabling, you need to use Category 6A or better cabling. Or if you are running 10 Gbqs for up to 10 km, you need to use 10GBASE-LR SFP+with patch cord LC-LC.

Planning for Future Proofing

Maybe your network only provision 100 Mbps network connections to the desktop for now, even though the 1G Ethernet has become a ubiquitous standard. But suppose you are going to move to a new location and you need to install new cabling. Are you going to go with yesterday's best cabling technology or are you going to install something that will meet today's needs and your needs for the next few years?

Remember, the labor is the most expensive part of your project. While top-of-the-line cable won't be the least expensive option, you should consider reasonably high-end cable for your installation. Maybe you don't go with the absolute best, after all, many organizations won't need 10 Gbps to the desktop for quite some time but don't go for cheap, either.

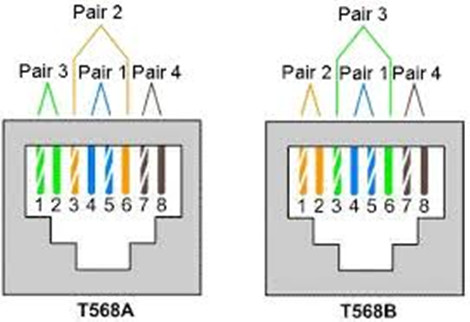

Following the Cabling Standards

Many users might have the fallacy that there are only eight individual wires inside a cabling jacket, so why not terminate them at random as long as you use the same scheme at both ends? Of course, that is the bad ideas.

The cabling standard known as EAI/TIA-568-A and B are existed for a reason. This standard defines how the cables are twisted and placed in the jacket. If you deviate from those standards, you risk introducing noise and inefficiency into your cable plant that can have a negative impact on overall network performance. The following image shows UTP Cable Termination Standards EIA/TIA 568A and EIA/TIA 568B, and the only difference is that the green and orange pairs are terminated to different pins.

Testing the Cabling Results to Ensure Cabling System Properly Functioned

Once the cabling is installed, you should test every cable using appropriate tools to make sure that it will be suitable for its intended use. Fiber optic testing of newly installed systems not only verifies that the system meets its design requirements, but also creates a performance baseline for all future testing and troubleshooting of that system to support the evaluation of warranty claims. The following image shows a Visual fault locator (VFL), designed with a visible laser and universal adapter like FC, SC and ST etc., which can help user easily locate faults on the fiber link.

This testing typically includes verifying length and cable specifications matched to needs. If you need 1 Gbps transmission speeds, verify that the cable's properties will support that need. This testing result will ensure that the data necessary to properly evaluate any future system malfunctions will be available.

Ensure a Quality Installation With Quality Fiber Optics

The amount of information carried in two strands of optical fiber would require a copper cable four inches in diameter. When considering the space constraints, required bandwidth, and long distance transmission needs in today’s applications, fiber optic products are the only viable choice. Easy installation and upgrades allow you to meet future growth needs and install spare fiber today for a more economical choice than installing additional cables later. FS.COM gives you quality products for all your fiber optic needs to reduce your risk of network failure.

Conclusion

To sum up, improperly installed cabling can cripple network performance, create maintenance headaches, and lead to hidden costs. Besides the above tips, you are supposed to increase error-free work with trained technicians. Because the best practice in cable installation is a professional with the proper tools and certifications to ensure the proper installation of the network cabling. Note that a beginner who has little experience in cable installation should be instructed under a professional technician to proceed the cable installation.

Oznake: cable installation, cable management

komentiraj (0) * ispiši * #

Proper Management of Fiber Patch Cord

srijeda , 01.06.2016.Past several years has witnessed a rapid deployment of fiber optic patch cables in optical communication networks. Compared with electrical cables, fiber patch cords (or called fiber optic jumper) are designed with enormous bandwidth capabilities, which make them preferred in digital and analog data transmission. These jumpers are fiber optic cables that are terminated at each end with connectors that plug into various pieces of equipment, available in single-mode and multi-mode patch cord versions (with OM3 patch cable widely used for short-reach transmission).

As fiber optic technology develops, the installation of fiber patch cords becomes increasingly easy nowadays. But to guarantee smooth networking performance, the proper patch cable management is essential. With proper management, it’s simple to go on cable operation and maintenance, saving time and cost. This article mainly discusses five factors that need to be considered during patch cord management.

Kinks, snags, pinches and poor contacts can dramatically reduce the performance of a fiber patch cord. The following factors are important in avoiding these problems.

Bend Radius

Since fiber optic cable made of glass has a fragile core, it requires great care and attention to avoid breaking this core during cable termination and operation. And in no case is fiber’s bend radius allowed. The minimum bend radius for patch cords varies with cord diameter. For 1.6mm and 3.0mm cords, the minimum un-loaded bend radius is 1.4 in (3.5cm), and for InstaPATCH Plus MPO patch cords, the minimum bend radius is ten times the cord diameter. If a fiber cable is bent excessively, the optical signal within the cable may refract and escape through the fiber cladding which will cause a loss of signal strength and is known as bend loss.

In addition, bending, especially during the installation and pulling of fiber patch cable might also cause micro cracks, and damage the fiber permanently. Generally, there are two basic types of bends in fiber, which are microbends and macrobends, with the latter larger than the former (as is shown below).

Patch Cord Path

This factor is closely related to the bend radius. The patch cable path should be clearly defined and easy to follow. Improper cable routing can lead to increased congestion in the termination panel, increasing the possibility of bend radius violations and possible failure in long-term. However, the well managed patch cable path ensures that bend radius requirements are maintained at all points, making accessing individual patch cable easier, quicker and safer. If the existing cord is the right length, it may be possible to re-use it. If this is the case, remove the cord completely and re-run it in through the cable pathways. This is the only sure way to ensure there are no tangles, kinks or strains in the cord.

Patch Cord Pulling & Stress

It’s not advised to use excessive force during the patching process, since too much force can stress cords and connectors, degrading their performance. If you need to use force in pulling a cord and there is something wrong, then stop and find the problem, and fix it before proceeding.

Patch Cord Accessibility

If the installed patch cable is easy to be accessed, the maintenance and operation would be quick without inducing a macrobend on an adjacent fiber. Accessibility is critical during network reconfiguration operations and directly impacts operation costs and network reliability.

Physical Protection

Patch cords that are routed between pieces of equipment can largely affect network reliability. Without proper protection, they would be easy to be damaged by technicians and equipment accidentally. Thus, physical protection of the installed patch cords is very important.

After discussing patch cord management, hers is another notice. Patching patch cord is critical in the first time, since its mistakes may cause disruption. Thus, after managing patch cord, taking time to make a final visual check on connections is a good investment. When patch panels are mounted in enclosures, ensure these are securely closed and, where necessary, locked, making sure that cord slack is not snagged or pinched by the doors.

Conclusion

Proper management of fiber patch cord can help to decrease operating costs and the time required to turn-up or restore service, making the operation reliable and flexible. As a professional fiber patch cord manufacturer, Fiberstore Cable Management provides ideal solutions for the distribution of cables and access to power, data and communication services on the wall and under the floor and for pole. Keep in mind those above-mentioned five factors, then the proper cable management is halt-succeeded.

Oznake: fiber optic patch cables, fiber optic jumper, OM3 patch cable, fiber patch cord manufacturer, cable management

komentiraj (0) * ispiši * #