Do You Have Any Idea of Water-Resistant Fiber Optic Cable?

srijeda , 21.09.2016.There is no doubt that fiber optic cables play an integral role in telecommunication industry. Applications like data centers, local area networks, telecommunication networks, industrial Ethernet, and wireless network are all needing fiber optics to ensure smooth connectivity. Each application requires a specific cable design based on performance requirements, environmental conditions, and installation type. The common fiber optic cables like LC to LC patch cord cannot adapt to the harsh environment (e.g. moisture environment or underground deployment), thus water-resistant fiber optic cables are highly demanded on the market due to their water proof nature. Here is what you should know about the water-resistant fiber optic cable.

Overview of Water-resistant Fiber Optic Cables

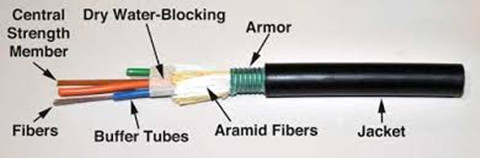

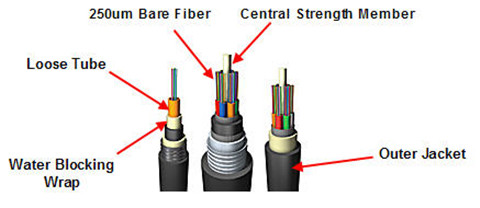

Water-resistant fiber optic cable refers to the special type of fiber optic cable that are designed and specified for installations where the cable will come in contact with water or moisture, such as aerial, direct buried, or in conduit. The cables in these applications are exposed to or can be temporarily submerged in water, so they contain either a water-resistant gel-filled or gel-free (dry gel) polymer.

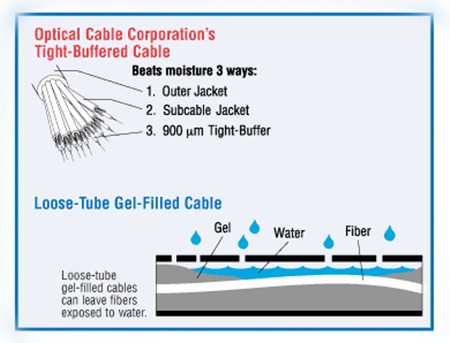

Generally, fiber optic cables can be divided into three types—outside plant cable (OSP), indoor/outdoor, and indoor, which are specified based on the environment and location where they are installed. With the exception of indoor cables, all cables contain water-resistant gel-filled or gel-free material to protect them from water and moisture. Before the use of gel-filled and gel-free materials, flooded core was another water-blocking method that is rarely used today (it has been replaced with gel-filled). The following image shows the gel-filled cables.

The gel is a gooey substance that must be removed when accessing and installing the cable. Gel-free cables, which are now more widely used, contain a super-absorbent polymer powder that is activated when it comes in contact with water or moisture. This blocks the water from penetrating the cable and allows for some expansion and contraction with temperature changes. Indoor cables do not contain water-resistant material since they are not typically exposed to water. Indoor (and indoor/outdoor) cables must meet additional flammability requirements dictated by local codes, such as the National Electrical Code.

Tight-Buffered & Loose Tube Cable Construction Provides Excellent Moisture Resistance

Water-resistant materials and cables are included in many industry specifications and standards. Generally, there are two basic water-resistant cable designs: Tight-buffer cables (primarily used inside buildings), Loose tube cables (used for OSP and indoor/outdoor).

It is known to all that most tight-buffered cable designs (seen in image below) are specified for indoor use, but some of them are designed with water-resistant powder and yarn, making them suitable for some indoor/outdoor applications. This tight-buffered cable utilizes an different design approach to deal with the moisture issue. Buffer materials are low-porosity plastics with excellent moisture resistance. This construction very effectively minimises the water molecule and OH-ion concentration level at the glass surface and virtually eliminates the stress corrosion phenomenon.

In loose tube cables (seen in image below), in order to prevent the water from reaching the 250Ľm coated fibers, the tubes surrounding the fibers must be filled with water-absorbent powder or gel that withstands high-moisture conditions, making them excellent for outside plant applications. This approach is especially made to waterproof the cable by filling the empty spaces in the cable with gel. The gel-filled tubes can also expand and contract with temperature changes, which makes loose-tube cable great for harsh, high-humidity environments where water or condensation can be a problem. However, gels can move, flow, and settle, leaves an uncertainty of the filled level of any particular point of a loose-tube gel-filled cable. Because loose-tube cable is typically 250 microns, you'll need a fan-out kit to build up the individual fiber strands to 900 microns when making the transition at the entrance point from outdoor loose-tube to indoor to tight-buffered cable.

The same level of protection remains in place all along the fiber, regardless of installation conditions, environment, or time. The balance of the tight-buffered, tight bound cable designs is such that it minimizes the open spaces available in the cable structure in which water can reside. Even if an outer cable jacket is cut, or water otherwise enters the cable structure, only a very small percentage of the cross-sectional area is open to water.

Conclusion

When selecting the suitable fiber optic cables, one must consider the application, the installation location, and the appropriate cable design and type according to specifications and standards. The water-resistant optic cable is specially made for moisture environment to insure the smooth connectivity. However, whether to have the loose tube fiber optic cable or tight buffered cable, it depends on the installation location. FS.COM offers a full range of fiber optic cables at very economical rates. These cables are widely used and are highly demanded on the market due to their water proof nature. In addition to this, we offer these cables in various fiber optic cable specifications, such as duplex/simplex fiber cable, single-mode/multimode fiber optic cable, LC/FC/SC/ST fiber optic cable and so on. LC to FC patch cord is absolutely high quality and low price, just as the other fiber optic cables. If you want to know more about our products, please contact us directly.

Oznake: Water-Resistant Fiber Optic Cable, LC to LC patch cord, LC to FC patch cord

komentiraj (0) * ispiši * #

10G Data Center Cabling Solutions

srijeda , 07.09.2016.The rapid development in data center throughput has led to the increasing usage and demand for higher-performance servers, storage and interconnects. And the old 1G Ethernet cannot handle the heavy-loaded solutions in data center any more. As a result, datacenter designers are looking to the expansion of higher speed Ethernet solutions, specifically 10 G and 40G Ethernet. As for 10GbE, there are two broad categories—SFP+ optical options and 10GBASE-T available on the market, which pose difficulty in selecting the appropriate 10-gigabit physical media. This article will make a brief introduction to these two 10G solutions to help you choose the suitable one.

What Is 10G SFP+?

10G Small-form-factor pluggable plus (SFP+) is the industry standard for data rates up to 10 Gbps, which is also MSA compliant. SFP+ module is especially standardized for 10 Gbps application, and is identical in dimensions to the SFP. To achieve the SFP+ form factor reduction, only the optical-to-electrical and electrical-to-optical conversion functionalities occur inside the optical module. The key advantage of SFP+ over the existing 10 G optical interconnects is the higher port densities enabled by its dimensions, and lower power consumption. Figure 1 shows a SFP+ modules connected with a LC to LC patch cord.

SFP+ transceivers are available in different 10G Ethernet standards—10GBASE-SR, 10GBASE-LR, 10GBASE-LRM, 10GBASE-ER, 10GBASE-ZR, 10GBASE-LX4 and 10GBASE-PR. Each standard has a unique specification that can be suitable for different applications. SFP+ optics are selected more often when designers need faster and more reliable solutions to handle 10 Gigabit Ethernet optical lines. With lower power usage and low latency, SFP+ ports are most commonly used for enterprise switches and also for plug-in cards for servers.

How Does 10G Copper Solutions Compare?

10G Ethernet can also run over twin-axial cabling, twisted pair cabling, and backplanes. SFP+ direct attach cable, 10GbASE-CX4 and 10GBASE-T are the common copper solutions for 10G short-reach interconnect. 10GBase-CX4 achieves the aggregate rate of 10 Gbps by transmitting over four independent cables at 3.125 Gbps. The disadvantage of this solution is the bulkiness of the cables that have eight twin-ax cables within them for a duplex link. And the bulkiness of the cables makes cable management more difficult. This becomes a significant limitation as the port densities and inter-port connection densities increase. Additionally, the number of conductors make these cables expensive compared to SFP+ cables.

10GBase-T enables 10 Gbps transmissions over Cat 6 and higher quality cables using complex signal processing and channel coding. The potential advantage of this technology is its extended reach. The extended reach and ability to enable structured cabling are not required for the short reach interconnects between servers and switches collocated in a rack. The disadvantages are its high power consumption and latency. The high latency in particular is a key limitation in latency sensitive data center and storage applications.

SFP+ Direct Attach DAC is another lower cost alternative to fiber with a limited link length of 7 meters. Additionally, it has significant power, cost, and performance advantages over the above media as explained below.

Why Use 10G DAC Cables in Data Center?

As 10 Gbps interconnects become ubiquitous in servers, providers are looking for a low cost, low power, and space efficient interconnect solution for the short reach (5-7m) links that dominate the data center environment. A length of seven meters covers all connections between server cards and switches, typically mounted on a single data center rack, and a vast majority of inter-rack connections. The SFP+ Direct Attach Copper is the 10G interconnect technology that matches these requirements, playing a vital role in enabling the next generation power and cost efficient data centers.

SFP+ Direct Attach Copper Solution

To further reduce cost and power in interconnect distances of 7 meters, which is sufficient to link server cards and switches, the SFP+ Direct Attach Copper replaces the optical modules and fiber with a passive copper cable with connectors identical to an SFP+ optical module. Figure 2 shows a SFP-H10GB-CU3M plugging in a Cisco switch. The reduction in cost and power are significant since the price of two optical modules required to support a full duplex link is approximately 10 times the cost of a fully connectorized SFP+ Direct Attach cable. In addition, the optical SFP+ modules consume around 1W each, adding 2W per port to the overall system power budget and cooling requirements.

Data is transmitted as 10 G serial NRZ (Non Return to Zero) symbols with transmit pre-emphasis and receive equalization compensating for Inter Symbol Interference caused by the board trace and the copper cable. This choice of serial NRZ transmission over a passive medium makes SFP+ copper both a low power and low latency solution compared to its alternatives.

Conclusion

As more emphasis is placed on energy efficient data centers and higher bandwidth applications, the need for a small form factor, low power, low latency and low cost interconnect makes SFP+ Direct Attach the optimal solution for short-reach 10G interconnects. While SFP+ fiber options provides a great path for higher performance long haul applications. FS.COM is a top manufacturer for DAC Twinax cables (SFP+ Cables, XFP Cables, CX4 Cables, Infiniband Cables, etc) and best suppliers for QSFP+ products including 10G & 40G QSFP+ copper and AOC cables. Optics transceivers like QSFP+, SFP, SFP+, XFP, X2, XENPAK, SDH, Bidi are also offered. If you have any interest in our products, you can contact us directly.

Oznake: data center, 10G cabling, SFP, DAC cables, LC to LC patch cord, SFP-H10GB-CU3M

komentiraj (0) * ispiši * #