Comparing UTP and STP Copper Cables

četvrtak , 22.12.2016.Many telecom professionals anticipated that copper cable would eventually be replaced by the fiber optic cable owing to its poor performance in higher-bandwidth application. However, copper cables like cat6/cat6a cable that can support up to 10Gbqs have proven themselves and been widely deployed in the home or office buildings. But for the copper cable, there exists the debate about unshielded twisted pair (UTP) vs. shielded twisted pair (STP). Thus this article aims to provide the detailed information about UTP and STP cables to help users make an informed decision.

Alien Crosstalk (ANEXT)

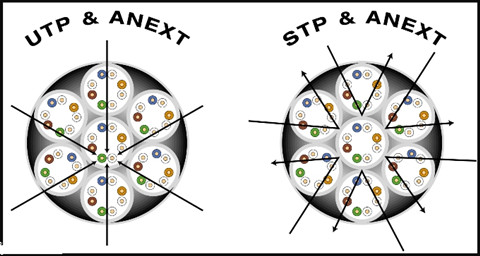

We all know that copper cable suffer from higher signal loss than fiber optic cable and can be easily interfered by the nearby powers or generator. Alien crossstalk is the performance parameter in copper cables, especially the UTP cables. The following image demonstrates different reactions of the UTP and STP cables to the ANEXT.

So what is the Alien crosstalk? Alien Crosstalk (ANEXT) is a crosstalk that occurs between adjacent cables and connecting hardware. Alien crosstalk in high-speed application is far more severer than in lower-bandwidth infrastructure. It might not be a problem at the lower frequencies of cat 5e and cat 6a cables, but the limiting noise source of the cat 6a systems.

In UTP copper cabling, the alien crosstalk will increase when adjacent cables are close proximity, which is indeed a nightmare to users. Therefore, it is typically recommended to let cat6a cable lay loosely in pathway instead of tight, twisted bundles. People usually have the misconception that if they use STP cables, then alien crosstalk would not be a problem. However, if the shield is not terminated correctly even a shielded system can fall foul of alien crosstalk.

UTP and STP Copper Cable

Twisted pair cables are widely used in transmitting information, especially across great distances. The twist in the wire cancels out any magnetic interference that may develop in the wiring. There are two common types of twisted pair cabling, STP and UTP.

Unshielded Twisted Pair (UTP)

Unshielded twisted pair cable has four pairs of wires inside the jacket. Each pair is twisted with a different number of twists per inch to help eliminate interference from adjacent pairs and other electrical devices. Unshielded twisted-pair cable does not rely on physical shielding to block interference. It relies instead on balancing and filtering techniques using media filters, baluns or both. Noise is induced equally on two conductors and is canceled out at the receiver.

With properly designed, manufactured and installed UTP cable, the network is easier to maintain than one in an STP cable plant, with its shielding continuity and grounding issues. UTP cables can be found in different categories, for instance, cat 5 UTP for specifications to 100 MHz and cat 6a UTP cables for specifications to 500 MHZ. Best buy Ethernet cable you can afford, most small business would purchase Cat 5e or Cat 6 cables.

Shielded Twisted Pair (STP)

Shielded twisted pair cable contains a hidden metal coating that protects wires from radio and electromagnetic interference. How effective the shielding is depends on the material used for the shield, its thickness and frequency, the type of electromagnetic noise field, the distance from the noise source to the shield, any shield discontinuity and the grounding practices. Also, crosstalk and signal noise can increase if the effects of the shield are not compensated for.

When people install and maintain them properly, STP cables greatly reduce crosstalk. This enhances dependability and boosts data transmission speeds in buildings that contain microwave equipment, HVAC systems or radio transmitters. There are many acronyms used on the market to describe shielded cables, from STP to F/FTP; while many are often used synonymously, nearly all of them have different meanings. This blog provides basic information about each style, as defined by ISO/IEC 11801:200, to clear up the confusion.

F/UTP (FTP)

An overall foil shield (F) with unscreened twisted pairs (UTP). This cable is very much like common UTP cables, with the addition of foil underneath the main cable jacket. Another common name for this cable is FTP. F/UTP cables are common in 10GBaseT applications.

S/UTP

An overall braid screen (S) with unscreened twisted pairs (UTP). This is occasionally referred to as an STP cable, but beware: There are other shielded cables among this list that may also claim this term. To be sure, always check to see whether your cable will have any kind of overall barrier, and whether the individual pairs have their own shield.

SF/UTP

Both an overall braid screen (S) and foil shield (F) with unscreened twisted pairs (UTP). This cable is also occasionally referred to as an STP cable. Cables with an overall braided screen are very effective at protecting EMI from entering or exiting the cable, but heavier, thicker and more difficult to install than its UTP counterpart.

S/FTP

An overall braid screen (S) with foil screened twisted pairs (FTP). The ‘shield’ underneath the jacket is a braid, and each individual pair is surrounded by its own foil barrier. The purpose of the additional foil on individual pairs is to limit the amount of crosstalk between them.

F/FTP

An overall foil shield (F) with foil screened twisted pairs (FTP). Similar to F/UTP cables, these shielded cables are commonly used in 10GBaseT applications.

U/FTP

No overall shielding or braid (U) with foil screened twisted pairs (FTP). This type of shielded cable is commonly used in 10GBaseT applications as well.

To sum up

- STP cables are shielded, while UTP cables are unshielded.

- STP cables are more immune to interference and noise than UTP cables.

- STP cables are better at maximizing bandwidth compared to UTP cables.

- STP cable cost more per meter compared to UTP cables.

- STP cables are heavier per meter compared to UTP cables.

- UTP cables are more prevalent in SOHO networks while STP is used in more high-end applications.

Which One Should I Use?

A key factor in this decision is an analysis of how prevalent EMI will be in the installation environment. EMI is commonly caused by nearby motors, generators, air conditioners, and even office mainstays such as fluorescent lights and printers. EMI can cause crosstalk between circuits, resulting in degradation of data, increased errors and slower transmission rates.

While even UTP cables reduce some EMI, shielded STP cables more effectively block interference. STP cables are ideal for high-speed networks such as data centers where 10GBase-T networks are used because 10G Ethernet is significantly more sensitive to EMI. Shielded cables also come in handy when installers must run wires next to fluorescent lights, microwave ovens or powerful motors.

STP cables are also used in outdoor environments where the cables are exposed to the elements and man-made structures and equipment that may introduce additional interference. It also stops criminals from using jammers to interrupt communications between cameras and indoor monitors or recording equipment.

However, people use UTP cables in the vast majority of homes, offices, and even in large scale businesses due to its lower cost. Unshielded phone and network wiring performs well in most buildings. If you don’t have major concerns about interference, it’s wise to avoid the cost and complexity of STP wiring.

Note that shielded cabling is more expensive than unshielded cabling and more difficult to install; it’s stiffer, making it less flexible. The cable also has a larger diameter, taking up more space in conduit. UTP, on the other hand, actually provides faster transmissions in the absence of EMI. It’s less expensive to purchase, easier to install and has been the standard for many years, so it’s already in place in most existing installations.

Conclusion

It is really doesn’t matter whether you use STP or UTP cables, make sure to install high-quality cabling. High-quality cabling will get you out of the trouble, reducing long-term replacement and labor costs. FS.COM offers a full range of UTP and STP copper cables with great customer feedback. If you are still not sure what type of wiring you need, please visit fs.com.

Oznake: UTP, STP, copper cable, best buy Ethernet cable

komentiraj (0) * ispiši * #

Eight Factors Influencing Your Fiber Optic Installation Bills

petak , 16.12.2016.Nowadays more than one third of the popularity have access to the internet. Large enterprises already use the high-capacity fiber-optic access networks, and small- or medium-sized businesses also want to relieve the bottleneck of the copper-based access network and benefit from the fiber-based access network. Nonetheless, costs is one of the factors that small business would take into account. In fact, the cost of large-scale fiber optic deployments depends on a wide range of factors, including redundancy and survivability need, access to the closest fiber line, labor cost, Aerial vs. Underground, and the fiber maintenance cost. The following article concludes several factors that will have great impact on the costs of building a fiber optic network.

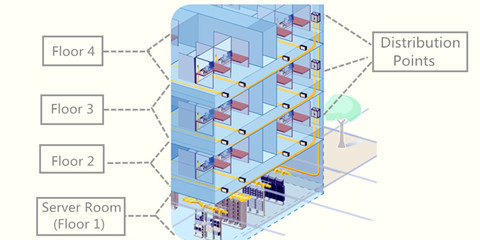

Figure 1 shows the layout of the fiber optic network in an office building.

Reminder:

Every building is situated differently, has different surroundings, different neighbors, and different physical dynamics influencing access to fiber lines, how much you’d have to spend on installation will be determined according to the specifics situation. Therefore, the factors listed below can not fit every situation. And we will not present the available materials that are likely to be used in you network as each installation requires its own assessment to determine final fiber optic network.

Redundancy and Survivability Needed

In a network designed with redundancy in mind, each portion of the network is constructed as part of a ring and economical construction is possible. On the other hand, when redundancy is constructed after the fact, it requires a custom cable pathway, usually doubling (or more) the construction cost.

Recently nearly 99 percent of the network will need two redundant physical paths from the network to its location, along with an electronic infrastructure to accommodate failure of a fiber route or an electronic component, and backup power of sufficient duration. And it also need to provide a 24-hour network operations center, a fiber repair crew, intrusion detection, and backup management and recovery facilities.

If network users do not require this level of availability, the network operator should determine their actual current and future requirements, and which subset of survivability and redundancy tools are needed. Ideally, any needs for physical redundancy will be included in the initial project design.

Labor Costs

Although the fiber equipment costs have fallen, skilled labor costs have risen. So how can operators limit those high labor costs and still deploy a quality fiber network that can handle the bandwidth needs of today’s subscribers?

Labor typically forms the majority of the cost of construction—approximately 50 to 80 percent. Therefore the quantity of fiber strands and cables, a materials cost, is typically a secondary consideration. Labor costs are highly variable. For example, poor economic conditions may lead construction companies to reduce their fees, while mobilization of contractors may increase their bid rates if there is suddenly high demand for immediate construction. In general, large-scale ventures have an advantage in managing costs, because construction companies feel comfortable offering lower rates when they expect to profit from the volume and duration of a project.

Ability to Reuse Existing Infrastructure

Reuse the existing infrastructure is not only a cost-saving solution, but an eco-friendly option for overall users. There are a number of options for using existing cable infrastructure. For example, if there is sufficient space in the existing conduit, then you can take advantage of conduit by adding new capacity to your building, which will make your installation substantially simpler and cheaper. Furthermore, whether the existing conduit already lead straight up into your building, or it is configured through twists and turns will have a major impact on the costs of its installation. That’s it, winding paths are trickier than straight cables.

Let’s solve a problem in arithmetic. The cost of a 6-count fiber cable is $2,000 per mile, while an 864-count cable is $50,000 per mile, implying a marginal cost of approximately $50 per fiber per mile. Actual costs for fiber purchase or lease, of course, reflect market costs and depend on the total availability of fiber over the route—and are thus, typically, considerably higher; however, fiber lease or purchase may be a serious consideration over routes where construction is difficult or costly and considerable fiber has already been installed.

Aerial vs. Underground

Typical construction is a mixture of aerial and underground techniques, in part because aerial construction also is more vulnerable to extreme weather, particularly in wooded areas and areas with frequent ice and high winds. And another reason is that aerial construction may be more expensive when poles are crowded or when the utility pole owner charges high rates for access. Worst-case costs can be $100,000 per mile (which usually would lead a network owner to build underground or over another route).

Underground construction also has a wide cost range. In areas where restoration is not important and long continuous runs are possible, “plowing” the fiber into the ground is an inexpensive option—approximately $70,000 per mile. For more detailed information about aerial and underground construction, please see an article entitled “Whether to Go for Aerial or Underground Deployment”.

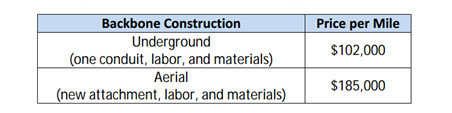

Based on the estimated percentage of aerial and underground plant we identified in our field survey, we estimate that the difference between aerial and underground construction in Santa Cruz is more than $80,000 per mile, as shown in Table 2.

Table 2: comparison of estimated aerial and underground construction costs.

Cable Management

Of cause, wire management is the most important part of any installation, especially for data communication. For better cable management in server room or the data center, IT racks, fiber enclosures and patch panels should be used. To determine what type of panels you need, take into consideration the space that will be utilized for the network. If you are installing inside of a closet or other cramped quarters and need low density, wall mountable panel is the best choice because it does not take up a lot of room. If racks are already in place, or if there is enough room to install them, rack-mount tray is the best choice because it is sturdy and easy to access. Keep in mind that rack-mount tray does not protect against environmental conditions.

Figure 3 shows the required equipment for better cable management.

Open frame racks are suggested for this server room, which can provide more flexible cabling environment. The using of fiber enclosure and adapter panels should depend on the fiber count.

The Location of Your Network

The single greatest determining factor not only to how much installation costs, but also how difficult it is to accomplish. Is fiber local or close to your office building? Or do you have to cross a state highway to extend fiber into your site? The nature of the physical terrain that the fiber needs to traverse to reach your building becomes significant. If you have to cross a state highway to bring the nearest fiber to your building, overcoming that obstacle will significantly impact the overall costs. Special use areas such as historical sites can often cause a problem for bringing fiber directly to your building. If there are any of these sites nearby your location, they could potentially impact the costs of fiber installation, depending on the route fiber needs to take to your facility.

And when the fiber is brought to your building, do you have a telecommunications room with the necessary space for installation already available? If so, that will streamline your installation costs, and ensure connectivity continuity once the installation is complete. As you may be gathering, every potential wrinkle in the process of installing fiber has the potential to make it more complicated, and everything that does in fact represent a hurdle has the potential to make the final charges more costly.

Power for Fiber Technology

How easily is sufficient power for fiber accessible from your telecommunications room? If there is ample power available, or if an emergency generator can be used to insure up-time of activated service, then you will save in fees that would require the introduction of additional power capabilities.

Fiber Maintenance Costs

Fiber optic cable is resilient compared to copper cable and coaxial TV cable. The fiber itself does not corrode, and fiber cable installed over 20 years ago is still in good condition. However, fiber can be vulnerable to accidental cuts by other construction, traffic accidents, and severe weather. In other networks of this size, we have seen approximately 80 outages per 1,000 miles of plant per year.

The fiber optic redundancy from the hubs to the FDCs in the backbone network will facilitate restoring network outages while repair of the fiber optic plant is taking place. Depending on the operational and business models, you might be responsible for adds, moves, and changes associated with the network as well as standard plant maintenance. These items may include:

- Adding and/or changing patching and optical splitter configurations at hubs;

- Extending optical taps and laterals to new buildings or developments;

- Extending access to the FTTx network to other service providers;

- Relocating fiber paths due to changes such as the widening of roadways;

- Participating in the moving of utilities due to pole replacement projects;

- Tree trimming along the aerial fiber optic path.

Conclusion

If you are still with us, and concerns about the cost of the installing a fiber optic network, please do not feel hesitate to contact FS.COM for a free consultation. We’ll be happy to provide you with the perfect solutions that meets your specific needs, and clarifies all the above factors that contribute to the bottom line. We offer a full range of enterprise network solutions including the 10G/40G switches, optical transceivers, high-density fiber optic cables, etc.

Oznake: fiber cable, copper cable

komentiraj (0) * ispiši * #