09

�etvrtak

listopad

2025

What Is Linear Guides? A Comprehensive Overview

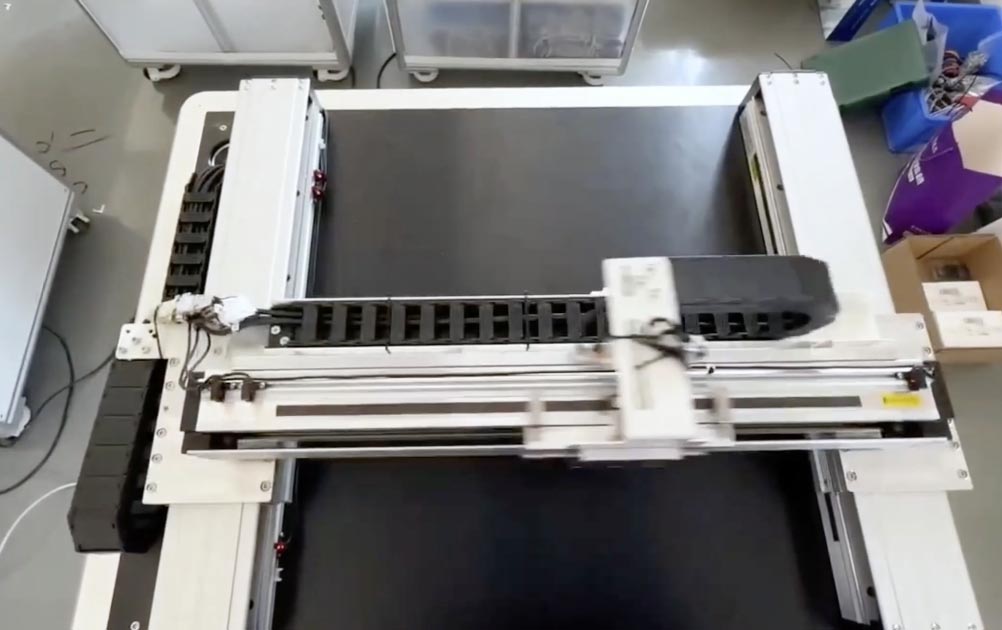

In the world of industrial automation and precision machinery, linear guides are one of the most important components for achieving accurate and repeatable motion. From CNC machines and 3D printers to semiconductor equipment and robotics, linear guide systems are the foundation of precise mechanical movement. This article explains what linear guides are, how they work, their major components, and why they are essential in modern industrial applications.

1. Definition and Function of Linear Guides

A linear guide, also known as a linear motion guide or linear slide, is a mechanical component that provides smooth, precise, and straight motion along a defined path. The basic function of a linear guide is to reduce friction between moving parts while maintaining rigidity and load capacity.

By combining a rail and a sliding block (often called a carriage), the linear guide system allows motion in one direction with minimal resistance.

Linear guides differ from simple bushings or sliding bearings because

they use rolling elements such as balls or rollers to support the load.

This design enables smoother movement, higher accuracy, and longer service life,

even under heavy loads or high-speed conditions.

2. Core Components of Linear Guides

A standard linear guide system consists of two main components:

- Guide Rail: A precisely machined metal bar, usually made from hardened steel or stainless steel. It serves as the path along which the carriage moves.

- Carriage (or Block): The moving part that slides along the rail. It contains rolling elements (balls or rollers) that minimize friction and enable smooth movement.

Inside the carriage, the rolling elements circulate through a closed loop,

returning to their starting position as the carriage moves along the rail.

This recirculating design allows continuous, stable motion without the need for lubrication between the sliding surfaces.

3. Types of Linear Guides

Linear guides come in several configurations depending on the application requirements:

- Ball Type Linear Guides: Use spherical balls as rolling elements. They are compact, low-friction, and suitable for applications requiring high precision and light to medium loads.

- Roller Type Linear Guides: Use cylindrical rollers instead of balls. They provide higher load capacity, stiffness, and resistance to deflection, ideal for heavy-duty or high-rigidity systems.

- Miniature Linear Guides: Designed for small-scale systems like semiconductor equipment, optical instruments, or medical devices. They deliver ultra-smooth and precise motion within compact spaces.

4. Working Principle of Linear Guides

The principle of linear guides is based on rolling contact motion.

When the carriage moves along the rail, rolling elements circulate inside the carriage.

This reduces the coefficient of friction from approximately 0.1 (sliding motion) to around 0.003 (rolling motion),

dramatically improving efficiency and reducing wear.

The preload, contact angle, and number of rolling elements determine the guide�s stiffness and performance.

Proper preload ensures minimal clearance between the carriage and the rail,

which improves positional accuracy and vibration resistance.

5. Advantages of Using Linear Guides

Linear guides are widely adopted because they combine high precision with mechanical efficiency.

Their main advantages include:

- High Positioning Accuracy: The use of precision-ground rails and rolling elements enables sub-micron level accuracy.

- Low Friction and Smooth Motion: Rolling contact minimizes resistance, resulting in smooth and consistent movement.

- High Rigidity and Load Capacity: The design supports both vertical and horizontal loads, making it suitable for complex systems.

- Long Service Life: Proper lubrication and material selection provide durability and resistance to wear.

- Reduced Maintenance: Modern linear guides require minimal upkeep compared to traditional sliding bearings.

6. Application Fields of Linear Guides

Linear guides are fundamental components across multiple industries:

- CNC Machines: Linear guides provide high-precision motion control for milling, cutting, and engraving operations.

- 3D Printers: They ensure stable motion of the print head and platform, improving printing accuracy.

- Robotics: Linear guides enable smooth and repeatable motion in robot arms, pick-and-place units, and assembly lines.

- Semiconductor Equipment: Used in wafer handling and inspection machines where sub-micron precision is critical.

- Medical Devices: Enable precision motion in diagnostic imaging systems and laboratory automation equipment.

For more real-world builds, application notes, and project logs using linear guides across CNC, robotics, and medical equipment, see this curated collection on my Rakuten blog:

Linear Guide Projects & Application Notes (Rakuten).

7. Key Parameters to Consider When Selecting Linear Guides

Choosing the right linear guide requires evaluating several performance factors:

- Load Capacity: Determine the maximum static and dynamic loads the guide can handle.

- Accuracy Grade: Precision levels range from normal to ultra-high (typically defined by ISO or JIS standards).

- Preload and Clearance: The amount of preload affects rigidity and backlash; select based on motion smoothness and vibration needs.

- Speed and Acceleration: Different applications demand different dynamic capabilities.

- Material and Coating: Stainless steel, chrome-plated, or coated versions offer resistance to corrosion and harsh environments.

- Lubrication and Maintenance: Built-in lubrication systems or grease nipples ensure long-term performance.

8. Linear Guides vs. Other Motion Systems

Compared to plain bearings or pneumatic slides, linear guides offer higher precision and rigidity. While bushings or shafts may be cheaper and simpler, they are not suitable for high-accuracy or high-load applications.

In contrast, linear guides provide stable performance across a wide range of operating conditions, making them ideal for demanding automation systems.

9. Installation and Maintenance Tips

Proper installation and maintenance are crucial for ensuring optimal performance:

- Ensure the mounting surface is flat, clean, and properly aligned.

- Apply uniform torque when tightening bolts to avoid deformation.

- Use clean, appropriate lubricants to prevent wear and corrosion.

- Periodically inspect rolling elements and rail surfaces for signs of damage or contamination.

- Follow manufacturer recommendations for re-lubrication intervals.

10. The Future of Linear Motion Systems

As automation and precision manufacturing continue to evolve,

linear guides are becoming smarter, more compact, and more integrated.

Modern systems are incorporating sensors for condition monitoring,

predictive maintenance, and real-time feedback control.

New materials such as ceramic coatings and self-lubricating composites

are being developed to improve durability and reduce maintenance needs.

Moreover, as collaborative robots (cobots) and AI-driven manufacturing systems emerge,

the demand for reliable and precise linear motion solutions will continue to grow.

11. Conclusion

Linear guides are the cornerstone of precise mechanical motion in modern automation.

They enable high accuracy, efficiency, and reliability across various industries.

Whether in robotics, CNC machining, or semiconductor equipment,

the role of linear guides is indispensable for maintaining stability and productivity.

For more technical resources and product specifications, you can explore additional details at Linear Guides Technology , where you�ll find in-depth insights and case studies related to precision motion systems.