Why Not Use the J-Hooks to Organize Cables?

subota , 18.02.2017.Have you ever been annoyed by the messy patch cables deployed in your cabling network? Did you take the cabling pathway as an ideal solution to manage the massive cables that provides better support to the cables? In fact, when deploying a high density network with large amount of cables, it is very necessary to choose the cabling pathway to manage the cables, which is generally made up of conduits, cable trays, ladder racks, surface raceways, and underfloor ducting systems. However, considering that it would cost a lot if we put every inch of the cable on the top of each support element to deploy the cabling pathway, this paper will introduce the J-Hook solution that can not only save the construction material but also provides well continuous support for the messy cables.

What Is the J-Hook?

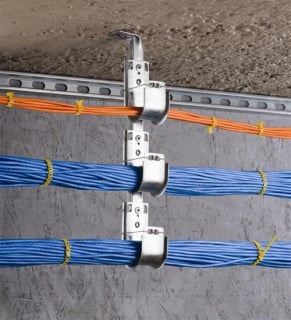

J-Hook is a common kind of fastener, usually made of galvanized steel but sometimes of plastic polymers, that is designed for giving support and management to the massive cables, so that the cables can be protected well and the performance of the high density network can be ensured or even improved. From the following figure, it is easy to find that the J-Hook has a J structure as its name implies. This J design with smooth beveled edges allows a large bending radius for cables, which also facilitates the cable installation. As for its application, you can learn it from the figure below that the orange and blue Ethernet cables are simply put on the J-Hooks and supported by the J-Hooks. You can mount it both in indoor and outdoor for managing and supporting the cables.

How to Install the J-Hook?

Installing J-Hook is as easy as using cable tie to manage the cables, which is very easy to acquire. Firstly, choosing a proper kind of J-Hook, which relies on where the J-Hook would be installed. Common locations J-Hook would be installed are wall, stud, beam, flange and drop-wire. Secondly, aligning snap lock attachment of J-hook with holes of the chosen bracket and snapping J-hook into position. Thirdly, ensuring that the intervals between J-hooks is about 1.2 m to 1.5 m. Fourthly, putting the cables in the J-hooks like the blue Ethernet cables in the figure above. And finally, checking the whole installation to see if the cables are managed well or if there is anything else wrong. If there is a need, just improving the installation to ensure the performance of the cables.

Common J-Hooks with Different Attachments

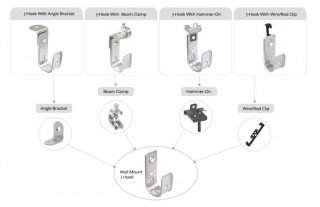

After knowing the procedures of how to mount the J-Hook, you may feel confused about the types of J-Hooks and which type is suitable for your application. In fact, there are some commonly used J-Hooks fitted with different attachments, J-Hook with angle bracket, J-Hook with beam clamp, J-Hook with hammer-on clip and J-Hook with wire/rod clip, which can be flexibly used. As for the structural differences of these four common J-Hooks, you can take the following figure as a reference.

J-Hook with angle bracket can be mounted in the ceiling, which is also a cost effective solution for the cable tray. As for the attachment of the 90-degree angle bracket, in can be easily installed or removed to meet your requirement. The second type, J-Hook with beam clamp, can be fasten to the horizontal flange that allows for up to 1/8 inch flange thickness. Unlike J-Hook with angle bracket, it can be rotated 360 degrees to support all directional cable runs. As for the J-Hook with hammer-on clip, it also features swiveling 360 degrees for various direction installation. Meanwhile, it can be fast mounted by the use of the hammer. As for the fourth type, its attachment is the wire/rod clip which is very similar to the bat wing, so it is also referred to as bat wing clip. The J-Hook with wire/rod clip can be attached to various structures with its bat wing clip.

Conclusion

In contrast to the traditional pathway elements, J-hook is easier and faster to install and move on-site that doesn’t need any special tool. Definitely, it is an good solution with high flexibility and ease of installation for horizontal cabling support, which is also cost effective with fewer logistical demands, less installation labor and lower material cost. Meanwhile, we can also learn from this paper that J-hook features several kinds of attachments that enables itself to be installed in different applications. Due to these advantaged, there is no doubt that J-hook will be used for more and more cabling networks.

komentiraj (0) * ispiši * #