How is Molybdenum Used in Modern Industry?

02.08.2019.In terms of global consumption structure, molybdenum is regarded as the ally of iron. In western developed countries, 80% of the molybdenum demand comes from steel, 30% from stainless steel, 30% from low alloy steel, 10% from drilling tool head and cutting tool, and 10% from cast steel. Another 20 percent of molybdenum consumption is in molybdenum chemicals and petroleum refining.

Alloy steel, stainless steel, tool steel, and cast iron are the main applications of molybdenum. Molybdenum is an important additive element in most superalloys and many nickel and titanium alloys. Molybdenum can accelerate solid strengthening and prevent chloride pitting at high temperature, so as to improve the antiseptic performance in reducing solution.

Silicon-molybdenum rod made of molybdenum powder and silica powder is widely used as a heating element in the electric furnace. Silicon-molybdenum rod can be directly used as an electrode in the fused glass and inserted into the glass material to melt the material around the electrode, so it can be used as corrosion resistance to the molten glass melting furnace of the glass electrode and parts.

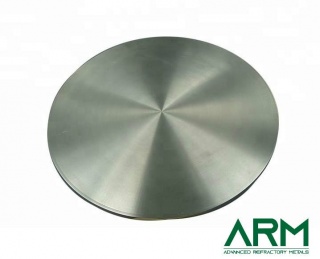

In addition, molybdenum films can be made as molybdenum targets on high-frequency sputtering, and uniform films of molybdenum with certain thickness can be made on the substrate, so as to form a conductive electrode and make glass devices. Besides that, molybdenum target photography has a high diagnostic value for breast diseases, especially for early breast cancer. Molybdenum discs can be used as an electronic component of high power and high-reliability semiconductor for heat dissipation.

The corrosion resistance of stainless steel is due to the fact that chromium naturally forms a thin protective passivation film on the surface of the steel, and molybdenum can strengthen the passivated film and regenerate the passivated film rapidly when it is damaged by chloride. The increase of molybdenum content can improve the corrosion resistance of pitting points and cracks in stainless steel.

316 Mo (2% ~ 3% Mo) is the most widely used stainless steel containing molybdenum, which is designated to be used as cans, pipes, and heat exchange materials for food processing and processing and for the production of pharmaceuticals. Increasing the molybdenum content can enhance the resistance to chlorine in the air, so the type 316 Mo can be used as an alternative material for offshore and coastal buildings.

Advanced Refractory Metals (ARM) supplies people with high-quality molybdenum products all over the world. Please visit https://www.refractorymetal.org for more information.

komentiraj (0) * ispiši * #