Marketing

Introduction to Several Cable Ties

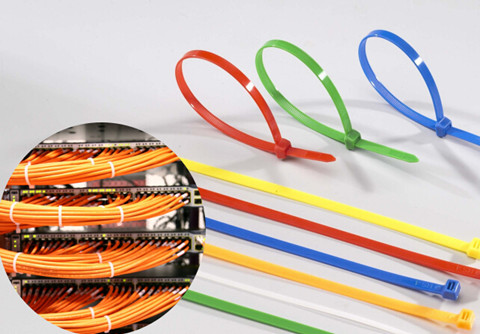

Owing to its low cost and ease of use, cables ties are ubiquitous in a wide range of telecom applications. Generally, cable ties, zip ties, or tie wraps are designed to hold items together, primarily the electric cables or wires. It is treated as a type of fastener. There are multiple types of cable ties available on the market today, such as nylon cable ties, Stainless Steel cable ties, and Velcro cable ties, etc. And each of them has their own features. So this article will introduce three common cable ties for you to select which cable ties suitable for the wire management.

Nylon Cable Ties

The common zip†ties, normally made of nylon, has a flexible tap section with teeth that engage with a pawl in the head to form a ratchet so that as the free end of the tape section is pulled the tie-wrap tightens and does not come undone. The Nylon material possesses an outstanding balance of properties, combined strength, moderate stiffness, high service temperature, and a high level of toughness.

Nylon cable ties are particularly resistant to repeated impact. They have a low coefficient of friction, and excellent abrasion resistance. But they should be stored in cool dry areas, out of direct sunlight, and sealed in the original packaging material. These measures will extend cable tie performance levels indefinitely. Nylon cable ties can be broadly divided into several cable ties: Colored Cable Ties, ID Marker Ties, Eyelet Cable Ties, and Releasable Cable Ties. An article entitled ďNylon, Velcro and Stainless Steel Cable TiesĒ has provided some detailed information about these cable ties.

Velcro Cable Ties

Velcro Cable Ties is made of soft hook and loop material, also known as hook and loop cable ties. They deliver reliability by protecting against over-tension of high-performance fiber and copper cables. These ties are adjustable, releasable, and reusable to effectively support frequent moves, adds, and changes (MACs). Moreover, a wide range of designs, sizes and colors provide flexibility and an aesthetically pleasing appearance. The key benefits of velcro cable ties are reliability, scalability and aesthetics. Velcro cable ties are very useful for computer and other data-cables as they will not crush the cables and cause damage.

Stainless Steel Cable Ties

The stainless steel cable ties either naked or coated with a rugged plastic, cater for exterior application and hazardous environments. This type of cable ties are made of stainless steel, which makes them much stronger and able to achieve a tensile strength of up to 400 pounds or more. Differ from plastic cable ties, you donít need to pull this cable tie to a tight close but through a through a self-locking mechanism. This mechanism can stand alone or be part of a ball lock system. What this locking mechanism does is add strength to the tie and ensure that it doesnít wear down or corrode when the temperatures get too hot or cold. The best part about this locking device is that you donít need much strength to feed the tie through. Stainless steel cable ties are ideal for applications that require a high-level of protection against corrosion and environmental conditions, which may cause typical nylon cable ties to disintegrate.

At the end of this article, one misunderstanding about cable ties needs to be explained. Cable ties, especially the plastic cable ties are generally viewed as single-use devices; they are typically cut off rather than loosened and reused. However, if a closed loop needs to be opened again, rather than destroying the cable tie by cutting, it may be possible to release the ratchet from the rack. While some cable ties are designed for reuse with a tab that releases the ratchet, in most cases a sewing needle or similar object will need to be interposed between the ratchet and the rack. Ties reused in this way will be weaker than new ones.

Conclusion

To sum up, this article has briefly introduced three cable ties. Each should be suitable for the unique applications. No matter what your installation requires, FS.COM is sure to have the exact zip or cable tie that you need. Please donít feel hesitate to contact us.

Post je objavljen 30.11.2016. u 10:09 sati.